Acoustiblok® Soundproofing Material

Barium-Free Viscoelastic Polymer Material

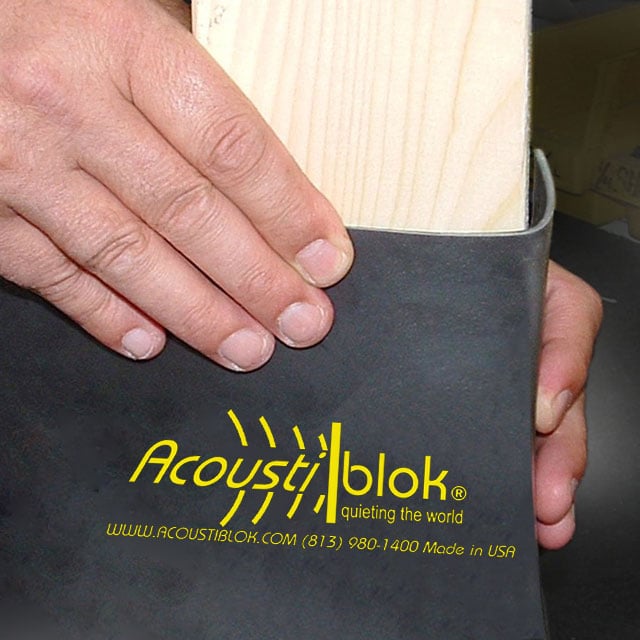

Acoustiblok Soundproofing Material – Acoustiblok is the name of both our company and our “Flagship” product. This product is used as a sound isolation material. It is typically installed before walls, ceilings and floors have been completed, thereby enhancing the Transmission Loss (TL) of these standard assemblies.

Acoustiblok is a U.L. Classified (UL # CLBV.R21490), viscoelastic polymer that comes in two forms. The first is Blok16, a 1/8th” thick sheet with a weight of 1 pound per square foot. The second is Blok32, a 1/4″ thick sheet with a weight of 2 pounds per square foot. Both are made from recycled plastics and non-toxic minerals that are mixed and pressed into a membrane sheet.

These sheets are then trimmed to a standard size of 54” wide x 30’ long and rolled up for easy transportation. The rolls weigh roughly 135 pounds each at this size. You can also order longer rolls ranging from 60’ long (at 270 lbs.), to 350’ long (at 1,575 lbs.), should you have a project with a larger area in need of treatment.

Acoustiblok® Soundproofing Material

continued…

Sound Transmission Classification

Acoustiblok® will typically raise the Sound Transmission Classification (STC) of any standard construction assembly. This is done by increasing internal damping, creating an airtight seal, and being flexible rather than rigid, unlike many construction materials.

Mass is important for sound isolation; as a result Acoustiblok ranges from 1 pound to 2 pounds per square foot. That’s a lot of mass for a material that is between 1/8” to 1/4” thick! But mass is not the only thing needed to lower sound across a wide spectrum of frequencies.

Offsetting Diminishing Returns

An increase of about 5 STC is typical for each doubling of surface weight. This is a great result for the initial doubling, but the cost of each additional doubling offsets the gains in STC due to the law of diminishing returns.

Due to these diminishing returns, the best way to achieve high levels of sound isolation is to build a heavy, limp, and airtight assembly. If you increase the mass of the assemblies while decreasing their stiffness, you will see significant gains in TL as a result. This is due to bending-wave coincidence, where a flexible or resilient material can result in a coincidental gain in TL of more than 15db at specific frequencies.

In the end, what does all this technical chitchat mean? Most of all it means we don’t want your boundaries (walls, floors, & ceilings) to be super heavy if it means they must also be super stiff and rigid.

It is noteworthy that sound travels efficiently through dense solids. And every type of sound can excite your boundaries, causing them to resonate at different frequencies. As a result of this, you should know the frequency spectrum of your offending noise before any attempt to design and build an enhanced boundary.

In Conclusion

For complex situations, including music mitigation, calling an Acoustical engineer can result in a solid investment that won’t give you a dip in attenuation! Please contact us to speak with one of our specialists.

Acoustiblok® Soundproofing Material

Video Gallery

Commercial Chiller Farm Partial Enclosures

Commercial Chiller Farm Partial Enclosures