QuietFiber®

QF2 – QF4 – QF6

Hydrophobic Industrial Noise Absorption Material

Performance

QuietFiber material is specifically engineered to tackle the frequencies of sound that are critical for noise reduction. QuietFiber’s Noise Reduction Coefficient (NRC), ranges from 1.0- 1.25 depending on the version (Q2, Q4 or Q6). An NRC rating of 1.0 or higher means there are no reflections off of the material.

Any material with an NRC that is greater than 0.50 is considered to be sound absorbing. If the NRC is less than 0.20, the material is considered to be sound reflecting. If the material has an NRC rating of say 0.60, it would have about 40% reflections off of the material. As a result, NRC materials are typically used for reflection control in spaces with high Reflection or Reverb Times (RT’s).

Appearance

QuietFiber is a form of mineral wool that is compressed into 4pcf, 6pcf or 8pcf, semi-rigid slabs. They are available in flat sections with lengths and widths measuring either 72″ x 16” or 72″ x 24”. They come in a black-faced finish.

QuietFiber® Panels Wrapped in Designer Fabrics

Applications

You can use QuietFiber® material for a variety of commercial, industrial and residential applications. In addition to reflection control, we recommend QuietFiber for damping the open cavities in standard construction assemblies (i.e., wall studs, floor joists, ceiling trusses). This is a VERY important aspect of sound isolation which most people either grossly mistreat or just plain overlook. And yet the data is conclusive; filling your construction assemblies with fiberglass batts, will only get you a few dB of attenuation within the frequencies that are used to calculate STC. In addition, you will have no information regarding frequencies outside of 125Hz-4kHz, which is the range covered by the STC tests.

Lower Frequencies

Most of the time walls fall short in the lower frequency ranges of attenuation. This is why a lot of sound can still be heard through a highly rated STC wall; those sounds are outside of the range of the STC test. Using QuietFiber in greater thicknesses and densities dramatically raises both the TL and the low frequency attenuation of walls, ceilings and floors. In most cases by an additional 4-5 dB over fiberglass treated assemblies. The gains can be even higher when you look at the TL of the frequencies below 125 Hz and above 4kHz.

So, what does all of this tech talk mean? It means that using QuietFiber, as opposed to the cheapest thermal insulation you can find, will make those empty voids in construction assemblies work to your advantage. With QuietFiber those voids will absorb huge bands of low frequency noise that fiberglass can’t!

Conclusion

We have found that, with everything acoustic, frequency and resonance are what it’s all about. To attain the highest level of performance for your situation, we recommend that you hire an acoustical consultant or acoustical engineer. Please feel free to contact us and speak with one of our product specialists.

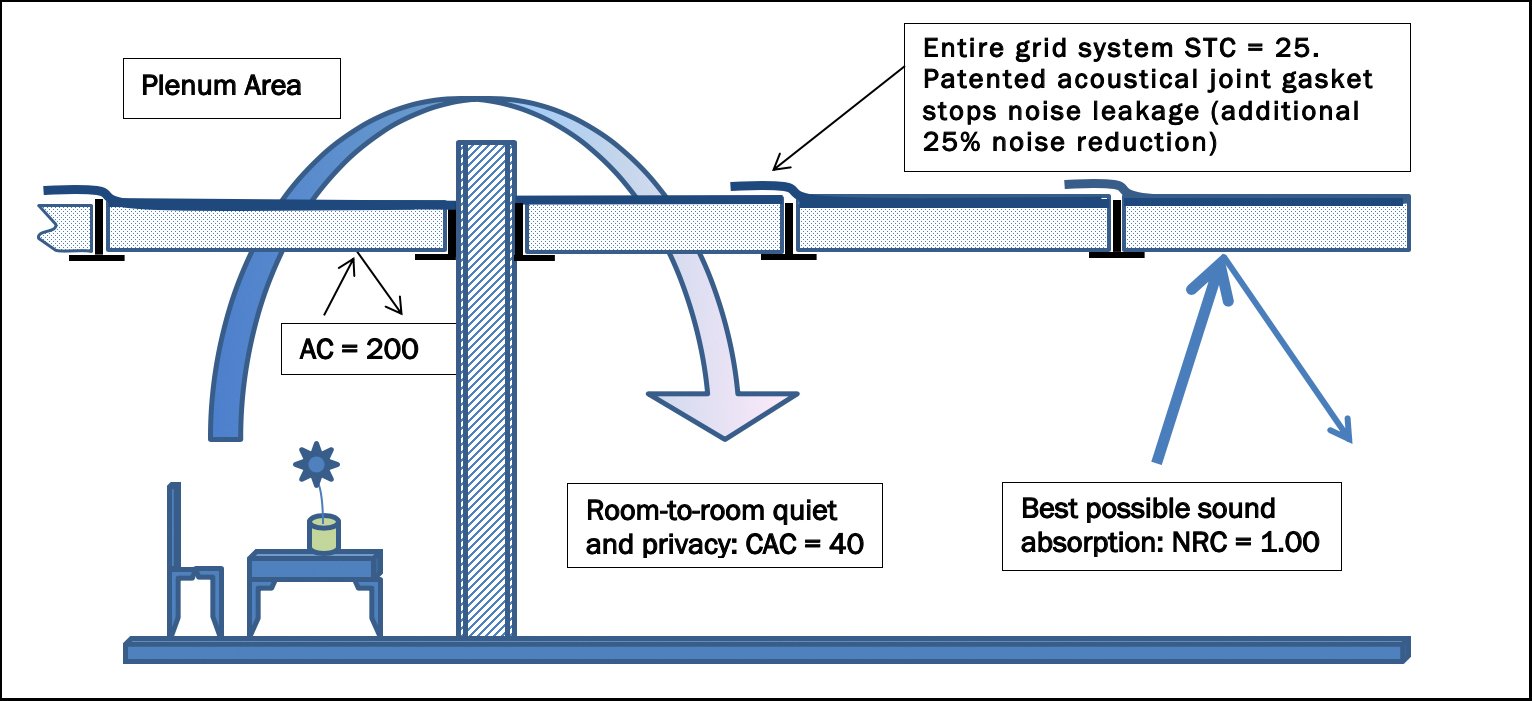

QuietFiber® Ceiling Tile Replacements – QF-CTR

High Performance Ceiling Tile® (patented)

Incorporating the patented acoustical joint gasket, this unique ceiling tile is designed to stop room to room sound transmission through the common plenum above the ceiling (CAC), which results in extraordinary “room conversation articulation” (AC) and maximum room to room privacy.

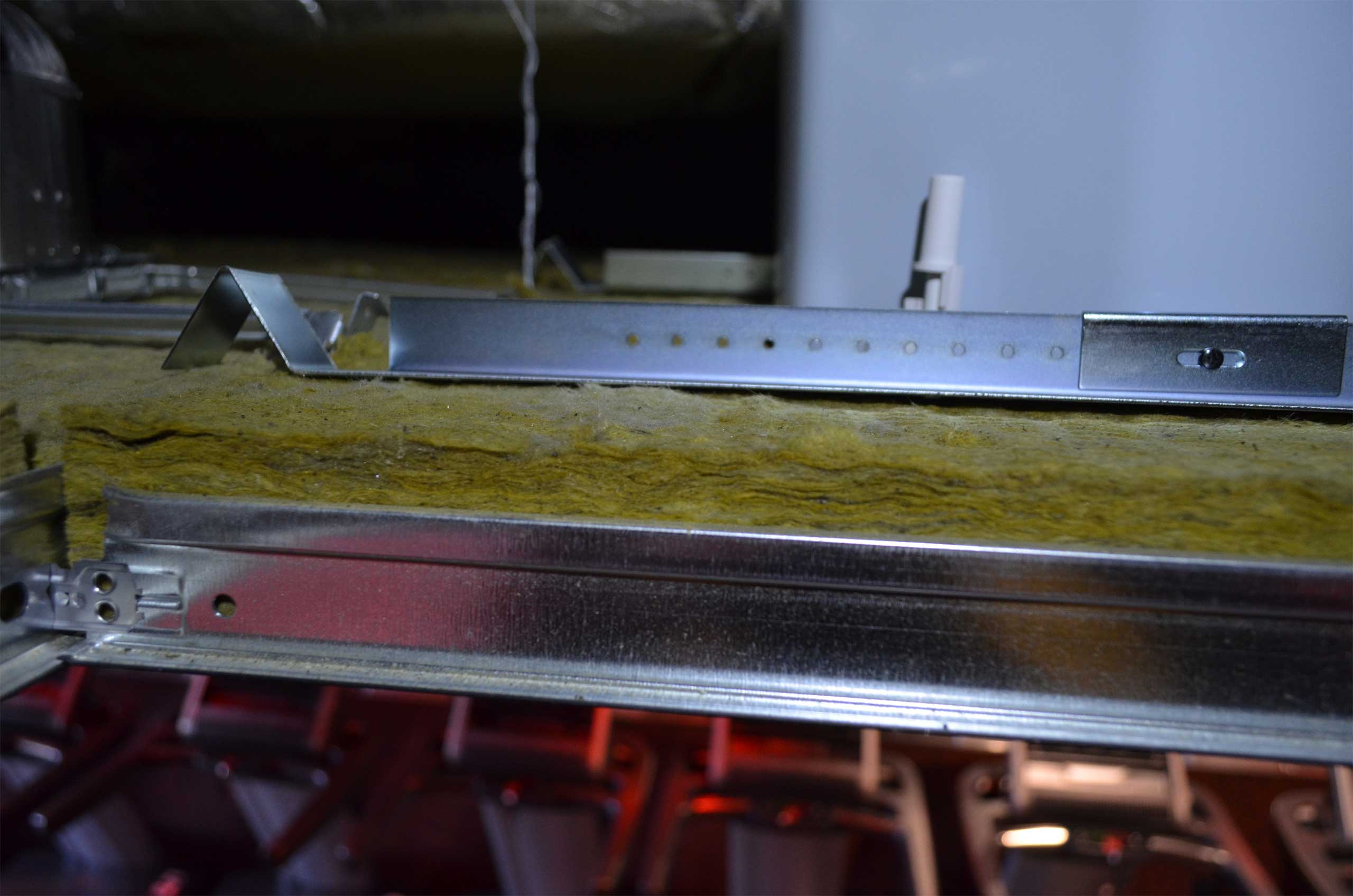

These images show what you will find above the drop ceiling, click anywhere in the gallery to see full size images.